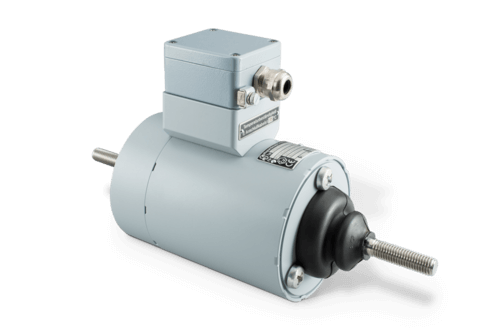

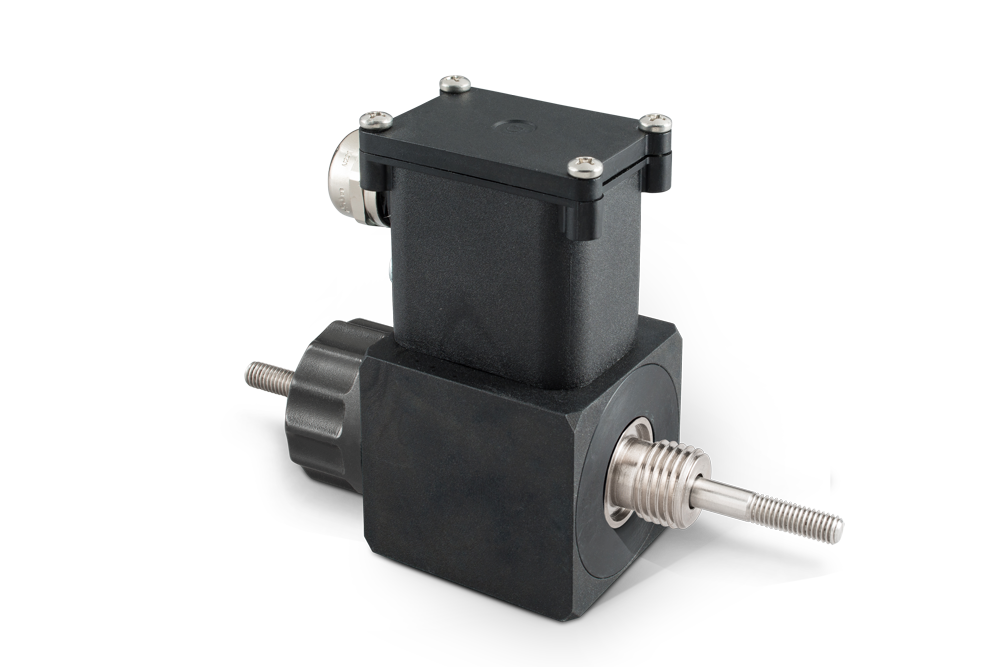

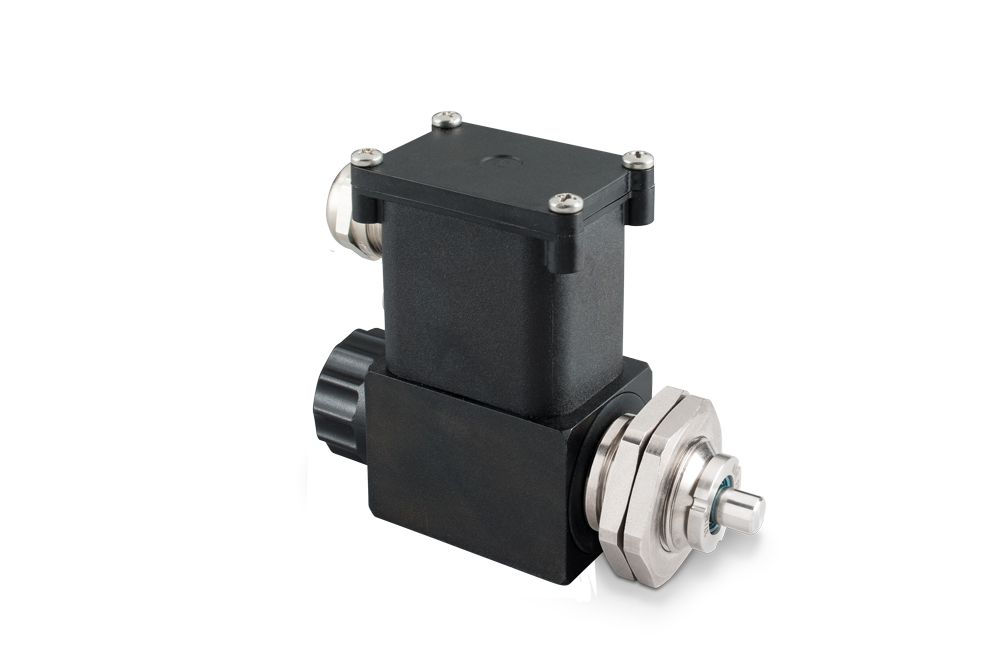

Devices to ATEX, IECEx

You intend to operate linear solenoids or valve solenoids in explosive atmosphere or in underground mining? Our broad programme of approved devices to ATEX and IECEx is your solution.

Our product programme includes devices for the application areas mechanics, pneumatics and hydraulics.

FAQ Explosion protection for solenoids

The questions explained in the following can only be rough information despite thorough research. When using solenoids in potentially explosive atmospheres, please adhere to the valid rules and guidelines as well as to the documents supplied.

What is explosion protection and when does it have to be applied?

Explosion protection contains all measures that help to avoid risks by explosion for persons and investment goods in businesses. Explosion protection is regulated by international and national norms and has to be applied whenever equipment or components are operated in areas exposed to explosive hazards.

So, solenoids have to be designed, manufactured and operated in such a safe manner that they are no risk of being a source of ignition, even in areas exposed to explosive hazards, and that they do not trigger explosions. This safety is confirmed by an impartial, official inspection authority and by an official sample testing. Industry and mining are subject to various (explosion-controlled) device groups. In mining, mine opening or deep mining, explosion control is called firedamp protection.

When do we refer to areas and/or environments exposed to explosive hazards?

All operators of industrial equipment are obliged to assess the explosion risks thereof, structuring the system in different risk zones which are assessed regarding the explosion risks contained therein.

The following issues will be discussed:

- Which substances and procedures are used? Are there any potential reciprocal effects?

- What is the probability and duration of a potentially arising explosive atmosphere?

- What is the probability of potential sources of ignition and that they generate an explosion?

- What impacts are to be expected as a consequence of an explosion?

If this risk assessment identifies a potential risk for part/s of the system, it is referred to as „area exposed to explosive hazards”:

Zone 0, 1, 2 for gas or

zone 20, 21, 22 for dust

Here, the following is essential: the smaller the number, the higher the risk of explosion hazards. This, in turn, has an impact on the extent of the necessary protective measures.

What do the expressions ATEX and IECEx mean?

The ATEX guideline determines the European admission procedure for devices which can be operated in explosive areas. IECEx is an admission procedure globally acknowledged. If a device has IECEx admission, admission according to the respective valid national norm is usually possible with comparably little effort.

What are the special features of explosion-protected solenoids?

As electrical components, solenoids principally bear various risks which might trigger an explosion in hazardous areas.

Here are some examples:

- Depending on the application, dimensioning and operation duration, the surface temperature of a solenoid might reach critical levels.

- By flaws regarding contacting, insulation and in potential compensation, electrical sparks may materialize.

- In case of odd material compositions, it is possible that mechanical sparks are created by colliding metal parts.

If a solenoid is admitted and produced according to ATEX or IECEx, certain technical characteristics, special quality assurance measures and exact descriptions make sure that the device is no risk when being implemented in areas with explosive hazards.

Which documents are supplied with the delivery of explosion-protected solenoids?

The corresponding operating instructions are provided with each device. An EU declaration of conformity is enclosed to each delivery.

+49 8331 1040

+49 8331 1040 info@magnet-schultz.com

info@magnet-schultz.com