Valve Solenoids for Hydraulics

You are looking for ON/OFF or proportional solenoids as drive for your solenoid valve or a pre-pilot or pressure reducing valve for oil and other fluid media and appreciate precise and innovative solutions?

We are specialists for low hysteresis, high compressive strengths, difficult ambient conditions in mobile and stationary applications and solve your task with our flexible modular system.

Frequently asked questions about valve solenoids for hydraulics

What are the technical differences between an on-off solenoid and a proportional solenoid?

A on/off solenoid has a rising characteristic curve and is operated at nominal voltage. The focus in the design is on the solenoid opening the valve against spring forces and pressure forces in the specified application range. The on/off solenoid therefore usually only knows the two switching states:

- de-energised in the initial position

- energised in the end position

A proportional solenoid has a horizontal or slightly descending characteristic curve. It is operated in a current-regulated manner. This means that its magnetic force is regulated by the current flowing through the coil. If the magnet works against a force, often a spring, a certain stroke occurs depending on the current. The focus here is on ensuring that the stroke occurs with the highest possible repetition accuracy and from both working directions and over the entire service life. The quality of the control behaviour is indicated by the hysteresis characteristic. This means that the lower the hysteresis, the more precise the control behaviour of the valve solenoid. Technical measures for achieving low hysteresis include the use of materials with special magnetic properties (so-called soft magnetic materials) and the use of particularly precise, low-friction and durable systems for the bearing of the armature. In addition, the electrical actuation also has an effect on the control accuracy.

What are the quality aspects of proportional solenoids or proportional valves?

The quality of proportional valve solenoids and valves is reflected in a number of product characteristics:

- High control performance and minimal hysteresis

- Slight change in control accuracy or hysteresis over the service life under real operating conditions

- In the service life (number of control strokes until failure)

- In corrosion protection and corrosion resistance

- Resistance to environmental influences

- Vibration

- Shock

- Media

- Resistance to humidity

- Protection class (IP...)

- Temperature resistance or high thermal class

- In the low level of variation between individual force-stroke characteristics in series production.

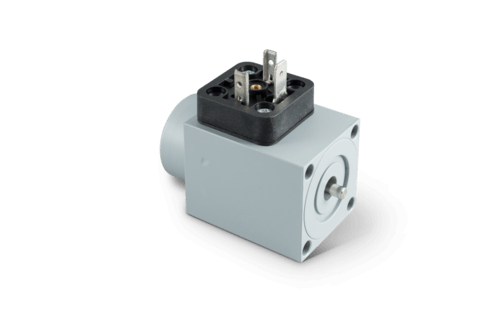

What construction types of valve solenoids are possible?

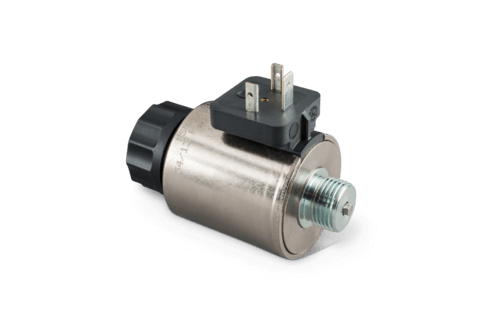

A distinction is made between the rectangular solenoid types GRFY, GAA and the round designs, known as the self-supporting systems FHTS/FHTP. Rectangular solenoids are the proven design that is mostly used today for replacement requirements or for applications in which particular robustness is required.

Round or cantilever-type designs consist of two main assemblies, the solenoid body and the tube, which are screwed together using a plastic nut. If necessary, the coil of the pressurised hydraulic system can be replaced or the coil connection can be rotated. In contrast to the square devices, the tube is not supported by the housing, it is ‘freely suspended’. This design principle has been established for many years. The reasons for this, in addition to the flexibility with regard to the solenoid body, are above all the cost efficiency.

For both designs, it is possible to integrate sensors for distance measurement. This is usually done as a customer-specific design.

How are valve solenoids electrically actuated?

The solenoid valve is usually electrically activated by the customer's electronic system. Magnet-Schultz provides all relevant information and recommendations with the technical data. At the customer's request, MSM also provides the suitable control electronics for activating proportional and valve solenoids for proportional and on/off applications.

How can the position of the armature of a valve solenoid be detected?

The position of the magnetic armature or the valve slide connected to it can be detected by sensors that are mounted on the valve solenoid at the factory according to customer requirements. In terms of the sensor principle, the LVDT is available for highly accurate applications and the Hall sensor for less demanding applications. Electronics integrated into the sensor convert the output signals into switching signals or a continuous signal. Common output signals are current outputs, voltage outputs and various CAN bus reports.

Can Magnet-Schultz also supply solenoid valves in addition to valve solenoids?

Yes. For many years, Magnet-Schultz has been delivering not only valve solenoids but also complete solenoid valves, usually as pilot valves or as special valves, mainly in applications of the drive train of passenger cars. Furthermore, we also have expertise in the development and manufacturing of valve assemblies, modules and units.

In which areas are valve solenoids used?

Valve solenoids are used in solenoid valves for all areas of modern hydraulics. Typical applications are categorised by industry as follows:

- Industrial hydraulics: injection moulding machines, bending machines, folding machines, presses

- Construction: construction machines such as excavators, wheel loaders or cranes, lifts

- Energy: wind turbines

- Agricultural machinery: tractors, implements, combines and harvesters

Does Magnet-Schultz also develop customised solutions for valve solenoids? What is the procedure?

Für Magnet-Schultz ist die kundenorientierte Gestaltung die übliche Vorgehensweise, sobald die Bedarfsmenge eine Modifikation oder Neuentwicklung rechtfertigen. Bitte nehmen Sie im Bedarfsfall mit unserer Vertretung oder unserem Stammhaus Kontakt auf.

For Magnet-Schultz, the customer-oriented design is the usual approach as soon as the required quantity justifies a modification or new development. In case of need, please Contact our representative or our head office.

Can I purchase spare parts for valve solenoids from Magnet-Schultz?

Nur bedingt. Im Bereich der Hydraulik belieferen wir unsere Kunden in der Regel mit kundenspezifischen Ausführungen. Diese werden ausschließlich an die jeweiligen Kunden geliefert. Darüber hinaus bieten wir Ventilmagnete für Hydraulik auch als Standardware an. In diesem Fall ist es möglich, die Magnetkörper Typ FHMG oder Typ FMME und Tuben Typ FHTP/FHTS im Rahmen der jeweils gültigen Mindestauftragswerte zu beziehen.

Only to a limited extent. In the field of hydraulics, we generally supply our customers with customised versions. These are supplied exclusively to the respective customers. In addition, we also offer valve solenoids for hydraulics as standard products. In this case, it is possible to purchase the solenoid body type FHMG or type FMME and tube type FHTP/FHTS within the scope of the respectively valid minimum order values.

What materials are used for the seals in the valve solenoids?

The seals are usually made of NBR, FKM or EPDM, depending on the specific requirements of the application. You can find the relevant information in the part list or the dimensional drawing.

Which protection classes (IP) are available for the valve solenoids?

The valve solenoids are available in various protection classes, including IP65, IP67 and IP69K. Generally, the selection of the electrical connection determines the protection class of the device.

In which temperature ranges can the valve solenoids be used for hydraulics?

The standard valve solenoids are designed for ambient temperatures of up to 50°C. If a valve solenoid is to be used in higher ambient temperatures, this can be achieved by using an adapted winding variant or higher-quality insulation systems. If the same materials are used in the insulation system, the electrical power and thus the magnetic force of the valve solenoid must be adapted.

How is the seal tightness of the valve solenoids guaranteed?

The tightness is ensured by precisely manufactured sealing surfaces and high-quality sealing materials.

How is the pressure resistance of the valve solenoids guaranteed?

The elementary component is the high-pressure-resistant pole tube, which is manufactured using special joining processes. The quality of such special processes is automatically monitored during production.

What special certifications are available for solenoid valves?

Valve solenoids with ATEX and IECEx approvals are available for use in potentially explosive environments. We can also obtain UL approvals upon customer request.

+49 8331 1040

+49 8331 1040 info@magnet-schultz.com

info@magnet-schultz.com