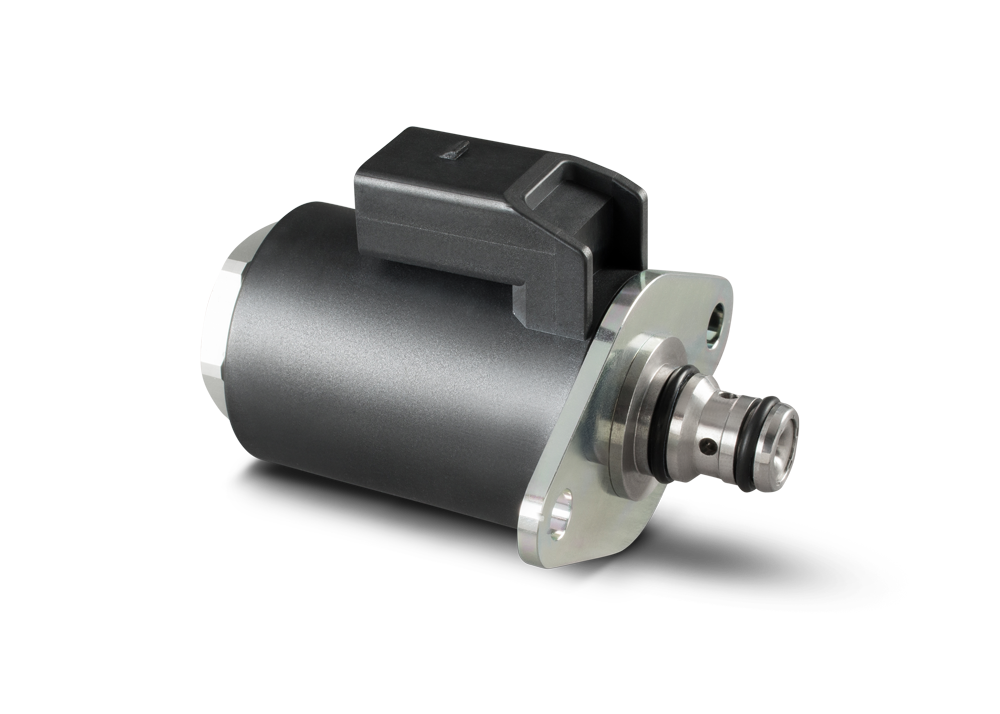

Valves for hydrogen storage and fuel cell systems

Gas-powered fuel cell systems need valves with considerably differentiated requirements in order to store and provide fuel with fuel gas such as hydrogen (H2) or natural gas (CNG) and in order to manage the compound wastes water (H2O) and nitrogen (N2)

Based on a flexible modular system, we develop and supply control and switch valves for customer-specific requirements in mobile and stationary applications.

In our development, we aim at the following aspects regarding our valves, dependant on their application areas:

- high pressures

- low leakage

- extensive service life

- high flows with little need for space

- temperature and vibration requirements

- protection classes up to IP6K9K

- fail-safe functions

- suitability of material in case of contact with high-pressure hydrogen

- testing according to EC79

Frequently asked questions about valves for hydrogen and fuel cells

When do valves for hydrogen require ATEX approval?

Due to the highly volatile behaviour of hydrogen, approval according to ATEX is generally not required for mobile applications. However, as soon as a valve is operated in a stationary application, approval according to ATEX may be required. Please always observe the relevant regulations in this regard.

How does Magnet-Schultz meet the special requirements of hydrogen in the valve technology?

Magnet-Schultz has been pursuing the development of hydrogen technology for years and has been developing hydrogen valves for 10 years. Therefore, we are highly familiar with the requirements concerning the valve technology, the materials as well as the sealing materials with hydrogen contact. By means of the most modern manufacturing and testing equipment, we ensure that the devices comply with the requested and, if necessary, agreed requirements.

In which voltages are the hydrogen valves available?

The standard voltages for hydrogen valves are 12V and 24V. In general, voltages of up to 120V can be realised as a special design after testing by means of an individual winding design.

How are the hydrogen valves electrically actuated?

All hydrogen valves are preferably actuated by a customer-side PWM (pulse width modulated) power supply. This allows the valves to be operated very energy-efficiently with maximum performance while at the same time optimising size, weight and costs to a minimum.

When actuated by PWM, the electrical energy supplied to the valve is reduced as soon as the valve is opened. This means that our valves make an important contribution to increasing the efficiency of the overall fuel cell system. Other actuation types require prior coordination with us.

How can incorrect electrical contact and connection of the valves be prevented?

In accordance with the Poka Yoke principle, plug codings can be arranged to prevent the incorrect connection of a valve.

In which performance range for the fuel cell are the valve solenoids from MSM used?

The valves are currently used in PEM fuel cells with an output range of 5-400kW. The valves are adapted by means of nominal diameters and, if necessary, the use of several valves. A large number of nominal diameters are already available in our modular programme. In addition, individual adaptations are possible.

In general, it is possible to scale the existing designs. Please contact us if you have a specific requirement.

For which temperature ranges are the hydrogen valves designed?

The standard valves are designed for use in temperature ranges from -40°C to +85°C. If necessary, the ambient temperature range can be extended within certain limits by adjusting the design. Limitations apply to the materials used, in particular to sealing and insulating materials.

Is there a storage programme for hydrogen valves?

Yes. For sampling, standard versions are available from stock in small quantities. Delivery is made exclusively to industrial customers. Deliveries of spare parts and replacement devices to end users are not permitted due to safety reasons.

How is the quality of the valves assured?

The devices are qualified and validated according to automotive and commercial vehicle standards. Attention is paid to the robustness required for mobile applications, which is essential for use in the field.

Each valve is 100% EOL (End of Line) tested at MSM and has a serial number to enable product traceability.

Does Magnet-Schultz also produce mechanically or manually actuated valves for hydrogen?

MSM currently only supplies electromagnetically actuated valves – in short, solenoid valves.

How are the hydrogen valves integrated mechanically, and are valve blocks available?

Usually, the hydrogen valves by Magnet-Schultz are installed in a valve block provided by the customer. The assembly is carried out via a flange, alternatively via a central thread.

For valves, standard valve blocks for flange variants are available for trial and test purposes. These can also be adjusted to special requirements of the application with respective demands.

Which nominal diameter is required for my application?

The nominal diameter of the devices depends on the maximum input pressure, the necessary flow and the resulting pressure difference or pressure delta. The basic design is usually done using the kv value, which is common in fluid technology. We can provide you with a calculation program for this to make an initial estimate.

In addition to the necessary flow, safety considerations can also influence the choice of nominal diameter.

Do valves have special requirements in terms of the purity class of the medium?

Usually slight contamination of the medium is not critical. Particles and fibres, which may arise, for example, during the production and assembly of the valve blocks, are trapped by the input filter in most of our valves. These input filters are not used to filter the operating medium, but to protect the valves themselves.

Information on technical cleanliness, the permissible particle size and the permissible residual contamination can be found on the respective dimensional drawing of the valve, which we will be happy to send you as part of an offer or if you place an order.

Are installation space models, interface descriptions and specifications for the installation position available?

Yes, after an initial assessment of the valve requirements, we will be happy to provide you with installation space models and a corresponding interface description with recommendations regarding the installation position.

My inspection service provider (TÜV; DEKRA;...) requires a manufacturer's declaration. Does MSM issue these?

Yes, with every delivery you will receive a manufacturer's declaration from MSM with a reference to the tests carried out and other applicable documents.

Are there any restrictions regarding ESD and EMC?

Our valves contain a passive coil, no electronics and have a closed iron circuit. When actuating the valves, a suitable protective circuit must be provided to protect against the switch-off overvoltage that occurs in coils.

Are valves with integrated heating available?

In principle, no additional heating elements are integrated in the valves. Especially for the drain valve, a version is available in which the valve part is designed for the integration of a customer-side PTC heating element.

+49 8331 1040

+49 8331 1040 info@magnet-schultz.com

info@magnet-schultz.com