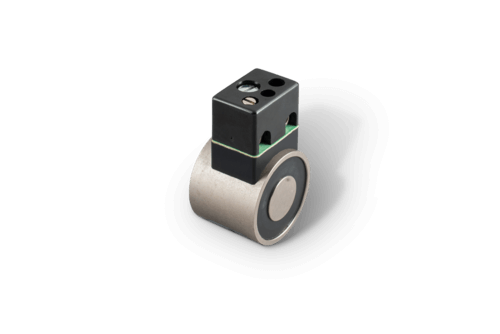

Holding Magnet type G MH

The holding magnet GMH builds up its holding force with application of the supply voltage.

Versions with polished pole face achieve maximum holding forces. If a corrosion of the bright metallic surface by environmental influences cannot be excluded, we recommend to apply versions with galvanised pole surface. These versions have a reduced holding force which, however, does not change, as long as the surface protection remains intact.

Sizes (Ø): 25 mm, 30 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm

Holding force: 135 N – 3300 N

- Increasing magnetic force vs. stroke characteristic

- Electrical connection via bipolar clamp of free flexible lead ends

- Fastening via tapped holes on the rear side

- Protection class: free flexible lead ends IP00, bipolar clamp IP20

- Voltage type: direct current, DC

- Pole surface galvanised

MAGNET-SCHULTZ GmbH & Co. KG