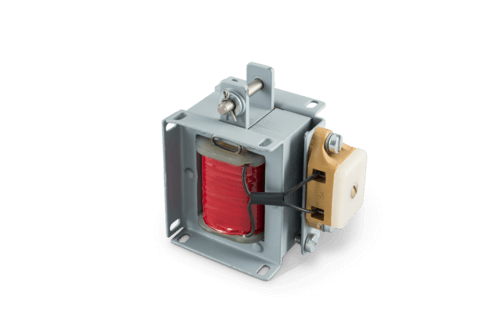

AC Solenoids Type W BA

Type W BA is a model range of robust single acting AC solenoids, well-proven for decades, which is preferably operated with mains voltage.

Compared to DC solenoids, AC solenoids are characterised by the following decisive advantages and disadvantages:

Advantages:

- High dynamics during the switching operation

- Large strokes (up to 45 mm)

- Automatic reduction of power consumption in the end position

- No rectifier necessary

Disadvantages:

- Limited number of switching operations per hour

- High noise emission when reaching and remaining in end position

- If, due to a mechanical failure, the armature does not reach the end position, the winding may burn, unless adequately protected.

As nowadays, direct current dominates as standard supply voltage for components, the applications for AC solenoids are limited to spare parts requirements and special applications where the required strokes cannot be realised otherwise and noise emission plays a minor role.

For new designs, we generally recommend the use of DC solenoids.

Sizes: 6 mm, 10 mm, 30 mm, 50 mm, 70 mm

Stroke: 20 mm – 45 mm

Magnetic force: 2.4 N up to 86 N

- Increasing and nearly horizontal magnetic force vs. stroke characteristic, depending on size

- Pull and push types

- Electrical connection via bipolar clamp

- Fastening with universal frame or dedendum angle

- Only for installation protected against contact

- Protection class: IP00

- Voltage type: alternative current, AC

Generally, we recommend the application of DC solenoids for new constructions.

MAGNET-SCHULTZ GmbH & Co. KG