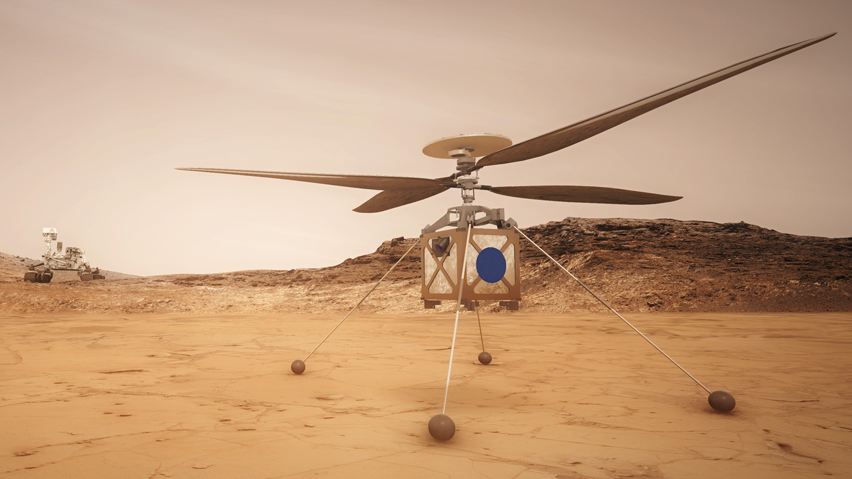

The aircraft developed by Jet Propulsion Laboratory (JPL) is navigated by six small electric engines. They control the inclination of the rotor blades and therefore the steering of the helicopter.

MSM Group supplies the electric engines‘ manufacturer with stator housings, which are precision swivel plates with an external diameter of 10 mm. In response to the message that parts of his team’s products are flying to Mars, Alejandro Aranada Muñoz, Plant Manager of W.E. Schultz in Rindal, CH comments as follows: „We are convinced that our products‘ quality contributes to our customers’ success – landing on Mars even exceeds our expectations. Though our contribution to the complete project might be very small, our customer’s success makes us proud!“

The „Mars tourists“ originate from a parts family consisting of 14 different housings which are produced in Rindal for ambitious customers. The specific challenges for these parts are the minimal admissible tolerances despite an extreme ratio between depth and very thin wall thickness.

In order to emphasize the engines‘ quality rating also by their look, an evenly shiny surface without shading must be achieved on the outer surfaces. When the surfaces are covered galvanically in the next step, even the smallest flaws would be visible as shading. Handling and transport damages are circumvented by removing the parts from the machine manually, depositing and packing them on special pallets. At the same time, dimensions and surfaces are controlled.

The customer selected W.E. Schultz as supplier since it was able to demonstrate unusual expertise, i.e. the ability to produce the precise parts on a 6-shaft-automatic lathe unit particularly economically. 6-shaft-automatic lathes are operated with parallel 6 spindles simultaneously. With each stroke, the spindles are moved on to the next processing station; at the last station, one part is completed with each stroke. Not least, the reference MSM with its superior parts for solenoid technology of a related product was a decisive factor.

+49 8331 1040

+49 8331 1040 info@magnet-schultz.com

info@magnet-schultz.com