Reliability, accuracy and fast installation are crucial for companies, especially when large quantities are involved – but in reality, things often look very different:

Time-consuming installation and lengthy calibration due to sensors with limited temperature compensation, complicated parameterisation and complex mechanical interfaces.

Redesigned for maximum operational reliability: our inductive transducers with CAN-BUS

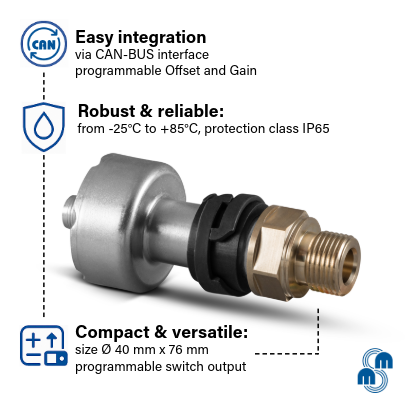

The linear, inductive transducer with CAN-BUS sets new standards for precision and efficiency. With compact dimensions of Ø40mm x 76mm, it offers maximum flexibility with a measuring stroke of ±4 mm, an integrated CAN-BUS interface and an additional analogue output. Thanks to its programmable switch output, 100% temperature compensation during EOL testing and a temperature range from -25°C to +85°C, it is equipped for even the most demanding environments. The IP65 protection class and reverse polarity-protected sensor input ensure maximum operational reliability.

Tailored to your requirements: our options.

Configure as required: options such as IO-Link, shorter measuring ranges and various mechanical interfaces make the sensor the ideal solution for individual requirements. Integration is quick and easy with an M12 plug connection.

The advantages of our sensor:

With the New Generation, you benefit from cost-optimised design without compromising on performance. Temperature drift compensation is performed inline. In addition, you can rely on protection against unauthorised sensor removal, as special tools would be required. Fast parameterisation of Offset and Gain via the CAN-BUS interface significantly reduces setup times.

The result: greater process reliability, reduced costs and maximum production optimisation – perfect for high-demand applications.

+49 8331 1040

+49 8331 1040 info@magnet-schultz.com

info@magnet-schultz.com